3D Printing is advancing healthcare and improving lives in Sierra Leone with 3d prosthetic legs and 3d prosthetic arms

3D Printing Industry Awards will use the money raised from its annual event to make a donation to charity. Merel van der Stelt from talks about how 3D printing can be used to change lives in Sierra Leone, West Africa, where 3D Sierra Leone is improving lives with 3d prosthetic legs and 3d prosthetic leg arms

3D Printing is advancing healthcare and improving lives in Sierra Leone with 3d prosthetic legs and 3d prosthetic arms

3DPI: Please tell me about your background and how you came to be involved with 3D Sierra Leone?

Merel van der Stelt, 3D Sierra Leone: Since 2018, I’m involved as project leader. After a successful short internship and 1-year graduation internship, I obtained a PhD position at RadboudUMC, supported by the Board of Directors of the Radboud UMC. In recent years, 40 students have been involved by doing internships at the University of Twente, the University of Delft, and the College of Arnhem and Nijmegen. With these students from different educational institutions, we set up a disciplinary team. Meanwhile, several departments of these universities and the RadboudUMC are involved, including the department of rehabilitation, the Orthopedic Research Lab, the 3D Lab of the RadboudUMC, and the prosthetic clinic: Papenburg Orthopedic. Using these collaborations, we have most of the required technical support in our team. With the help of this group of people, we have been able to make great improvements in the development of prostheses and the professionalization of the 3D lab at Masanga Hospital in Sierra Leone.

3DPI: What is the issue that 3D Sierra Leone is tackling?

Merel van der Stelt, 3D Sierra Leone: Access to prosthetic services is very limited in low- and middle-income countries. Facilities to produce prostheses are not within reach or too expensive. Current manual workflows are highly dependent on the prosthetist’s experience and skills, implying difficulty in quality assurance, standardization, and scalability.

A joint venture between the 3D lab at the Radboud University Medical Centre and the foundation 3D printing in developing countries started a pilot non-profit 3D lab in 2018 in the Masanga Hospital in Sierra Leone to produce prostheses for people in need. In recent years, we have conducted several scientific studies to investigate the added value of 3D technology in a rural hospital

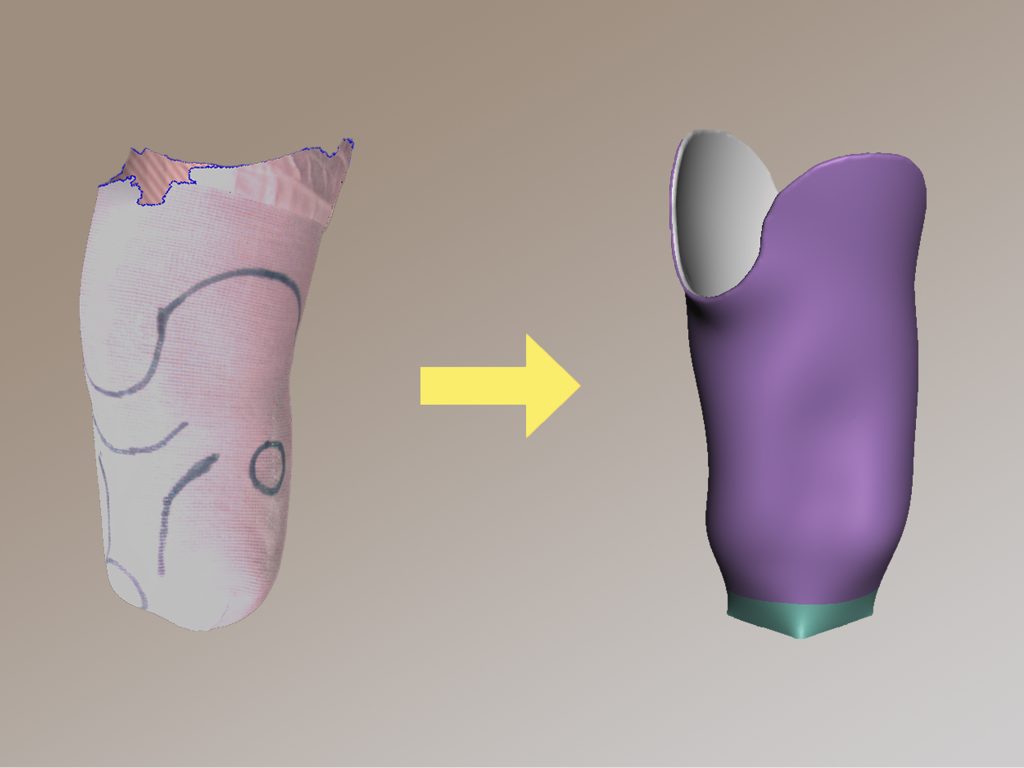

We apply computer-aided design (CAD) and computer-aided manufacturing (CAM) to produce low-cost prostheses. Using CAD-CAM techniques, the production process is consistent and faster. The entire process can be automated by following a standardized design workflow including Artificial Intelligence (AI) algorithms for patient-specific socket prediction. Socket fitting becomes less dependent on the individual prosthetist’s skills and experience, thus increasing successful prosthetic fitting rates.

The overall aim is to enable the local employees to produce prostheses independently. Simple digital automated workflows, using Artificial Intelligence based socket prediction, could offer a solution to improve prosthetic fitting in underserved regions worldwide.

3DPI: How are approaching this work, and what are some of the challenges?

Merel van der Stelt, 3D Sierra Leone: One of the biggest challenges is making the project sustainable. Our ultimate goal is that local employees will be able to make the prosthetics independently. For this, we are now developing new software that will enable a very easy production workflow. Another challenge is that we want to make the prosthetics as cheap as possible. A lower leg prosthesis now costs around 90 USD in materials. This does not seem like a lot of money, but most people in Sierra Leone cannot afford this amount. So it is a challenge to raise enough money to provide these people with a prosthesis. In the short term, we are therefore dependent on donations.

We intend to create different versions of the 3D Pro Flow, variable in complexity and therefore suitable for all countries. The 3D Pro Flow can be sold to countries according to income. We hope this can lead to a self-sustaining non-profit project whereby richer countries can contribute to prosthetics in poorer countries.

3DPI: How do you plan to develop the project in the coming years?

Merel van der Stelt, 3D Sierra Leone: Impact measurement: (1) The first measurable goal is that all 70 people who undergo an amputation annually in Masanga Hospital can be assured of a prosthesis made by the local employees independently. (2) In case of a successful introduction in 2023, we intend to scale up with a mobile workshop to provide prosthetic care to remote areas as well. (3) Simultaneously, we will reach out to other partners in other LMICs to scale up the project in 2024. This will lead to building more workshops and possibly starting collaborations with large organizations such as the Red Cross and Doctors Without Borders. An automated simplified production process and infrastructure of 3D-printed prostheses could be used by these NGO’s worldwide. (4) All our scientific work and clinical outcomes are published in international peer-reviewed scientific journals. (5) People with disabilities will be actively employed as a workforce wherever possible. To ensure the scalability of the project we work in close collaboration with the Ministry of Rehabilitation in Sierra Leone.

3DPI: How do you view the utility of 3D printing as a tool within developing countries?

Merel van der Stelt, 3D Sierra Leone: 3D printing does not necessarily have huge advantages, except that production is faster and is therefore cheaper. The biggest advantage is that we can now do the production process digitally. This gives the possibility to automate and standardize the whole production process, allowing people with limited knowledge of computers and prosthetics to make cheap prosthetics

The newly developed software package, including the AI model for automated socket prediction, is a step towards independence for local employees in low- and middle-income countries to produce prostheses. We aim to provide a complete package consisting of software, hardware, and training as a solution for the need for prostheses around the world.

3DPI: How can the 3D printing community help your work? What kinds of support are you seeking?

Merel van der Stelt, 3D Sierra Leone: It would be great help if people would like to donate money to the project for material and tool costs. For 90 USD, we can make a leg prosthesis with a 3D printed socket. With this donation you could completely change someone’s life. We also use donations for training and education of our staff and students studying prosthetics or physiotherapy.

In addition, we are always open to long-term funding to pay for research on the prostheses and software.

3DPI: Anything else you would like to add?

Merel van der Stelt, 3D Sierra Leone: There is a paucity of prostheses in LMICs due to a lack of materials, trained personnel, and high cost. With sustained prosthetic services, countless people can gain access back to societal participation and lead productive lives. This is what we are going to change profoundly with our project.

3D technology can contribute to improving the quality and scalability of prosthetics in LMICs. The purpose of providing 3D printed prostheses is to empower people with limited knowledge of both prosthetics and IT to independently produce prostheses. In this way, the rate and amount of successful prosthetic fitting will increase. We aim to improve the health and quality of life in remote and underserved regions worldwide.

The conformation about the importance and uniqueness of our project was demonstrated last year at the World Health Organization film festival, where our project won 1st prize in the innovation category.